Description

Applications

Nickel alloy UNS N08825 has many different industrial applications, some of which include: Propeller shafts, Phosphoric acid evaporators, Tank trucks, Hot vessels for food, water, sea water, Sulphuric acid piping and vessels, Marine exhaust systems

Standard

Rod, Bar, Wire and Forging Stock: BS 3076NA16, ASTM B 425, ASTM B 564, ASME SB 425, ASME SB 564, ASME Code Case N-572, DIN 17752, DIN 17753, DIN 17754, VdTÜV 432, ISO 9723, ISO 9724, ISO 9725.

Plate, Sheet and Strip: BS 3072NA16, BS 3073NA16, ASTM B 424, ASTM B 906, ASME SB 424, ASME SB 906, DIN 17750, VdTÜV 432, ISO 6208.

Pipe and Tube: BS 3074NA16, ASTM B 163, ASTM B 423, ASTM B 704, ASTM B 705, ASTM B 751, ASTM B 775, ASTM B 829, ASME SB 163, ASME SB 423, ASME SB 704, ASME SB 705, ASME SB 751, ASME SB 775, ASME SB 829, ASME Code Case 1936, DIN 17751, VdTÜV 432, ISO 6207.

Others: ASTM B 366, ASME SB 366, DIN 17744

Chemical Composition

| Ni | Fe | Cr | Mb | Cu | Ti | C | Mn | S | Si | Al |

| 38.0-46.0 | 22.0 min | 19.5-23.5 | 2.5-3.5 | 1.5-3.0 | .6-1.2 | 0.05 max | 1.0 max | 0.03 max | 0.5 max | 0.2 max |

Mechanical Properties

| Form | Condition | Ultimate

Tensile Strength, ksi (MPa) |

Yield

Strength at 0.2% offset, ksi (MPa) |

Elongation

in 2″ or 4D, percent |

| Sheet

Plate Strip, Bar |

Annealed

Annealed Annealed |

100 (689)

95 (655) 85 (590)a |

55 (379)

45 (310) 35 (240)a |

39

44 30a |

Weldability

Alloy 825 can be readily welded by the shielded metal-arc process using alloy welding electrode 135, the gas shielded arc processes using alloy filler metal 65, and the resistance welding processes. The alloy requires no postweld heat treatment. The corrosion resistance of deposited weld metal from both covered electrode and bare wire is equivalent to that of the parent metal.

Heat Treatment

Incoloy 825 is stabilise annealed at 940°C. The softest structure is obtained at 980°C. Sections heavier than sheet, strip and wire should be quenched to avoid sensitisation.

Corrosion Resistance

The outstanding property of Incoloy 825 is its corrosion resistance. In reducing & oxidising conditions, Incoloy 825 resists general corrosion, pitting & crevice corrosion, intergranular corrosion and stress corrosion cracking. It is particularly useful in sulphuric & phosphoric acids, sulphur containing flue gases, sour gas and oil wells and sea water.

Machinability

Incoloy 825 is classed as a ‘C’ alloy, and is reasonably easy to machine.

Quality & Testing

Fushun supply Certification with all shipments, containing full chemical analysis and also mechanical test results if requested.

All incoming material is visually inspected and PMI (Positive Material Identification) tested before processing begins and all our production material is checked during each stage of processing.

All incoming orders are produced to the individual customer specification, some of which may involve processing sample batches for testing prior to full production.

Final Inspection carried out on all finished material to include:

Visual inspection

Dimensional checks

PMI (Positive Material Identification)

Mechanical tests

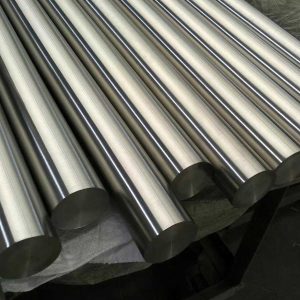

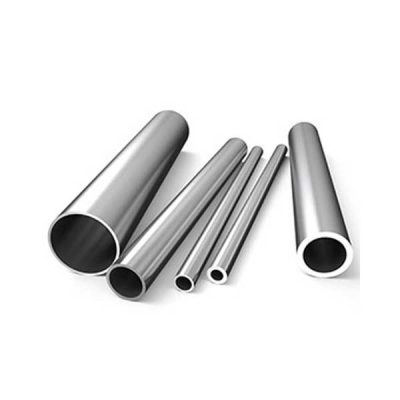

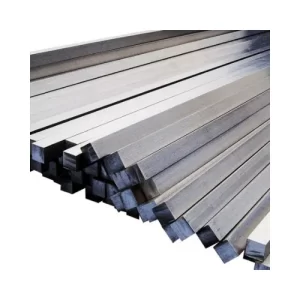

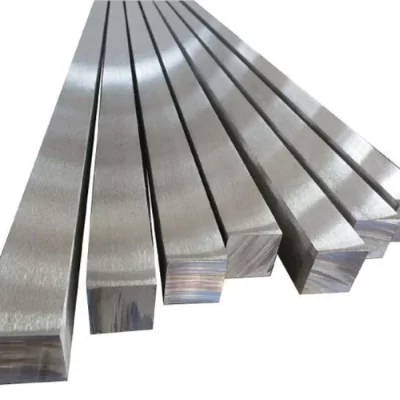

Nickel Alloy Material Available Formats

Fushun offers pure Nickel alloy materials in a variety of forms, including:

Seamless & welded pipe

Seamless & welded tube

Bar

Wire

Sheet

Plate

Forgings

Pipe fittings

Flanges

Weld Rod

We are Suppliers and Exporters of Incoloy 825 UNS N08825 2.4858 NiCr21Mo Nickel Alloy in Cities Like

Howrah, Haryana, Aberdeen, Jeddah, Courbevoie, Jamshedpur, Geoje-si, La Victoria, Kuwait City, Thane, Pune, Rio de Janeiro, Nagpur, Faridabad, Nashik, Calgary, Dubai, Dammam, Dallas, Vadodara, Edmonton, Indore, Riyadh, Kolkata, Pimpri-Chinchwad, Sharjah, Mexico City, Ernakulam, Australia, London, Visakhapatnam, Rajkot, Jaipur, Ranchi, New Delhi, Ahmedabad, Bangkok, Houston, Ahvaz, Muscat, Toronto, Caracas, Coimbatore, Perth, Al Khobar, Gurgaon, Jakarta, Milan, Ludhiana, Thiruvananthapuram, Navi Mumbai, Singapore, Manama, Bogota, Kuala Lumpur, Al Jubail, Chennai, Hong Kong, New York, Atyrau, Hyderabad, Colombo, Petaling Jaya, Hanoi, Ulsan, Madrid, Granada, Doha, Lagos, Turkey, Bhopal, Kanpur, Moscow, Bengaluru, Secunderabad, Vung Tau, Istanbul, Busan, Sydney, Seoul, Gimhae-si, Los Angeles, Chandigarh, Chiyoda, Tehran, Abu Dhabi, Baroda, Montreal, Surat, Santiago, Brisbane, Noida, Lahore, Algiers, Mumbai, Cairo, Karachi, Port-of-Spain, Ho Chi Minh City.

We are Suppliers and Exporters of Incoloy 825 UNS N08825 2.4858 NiCr21Mo Nickel Alloy in Countries Like

Iran, Bangladesh, Mexico, Ghana, South Korea, Peru, Nigeria, Macau, Libya, Iran, Argentina, Kazakhstan, Hong Kong, Serbia, Kenya, Nigeria, brazil, Bhutan, Chile, Norway, Greece, Finland, India, Turkey, Ireland, mexico, srilanka, thailand, malaysia, Ecuador, Trinidad & Tobago,Tunisia, Austria, Jordan, Estonia, Sweden, South Africa, Japan, New Zealand, Tibet, Afghanistan, Puerto Rico, Ukraine, Taiwan, Thailand, Hungary, United States, Singapore, Israel, Kuwait, Australia, Oman, Chile, Poland, France, Gabon, Brazil, Bulgaria, Vietnam, Croatia, Azerbaijan, Morocco, Switzerland, Poland, Algeria, Mexico, Romania, Zimbabwe, Saudi Arabia, Namibia, Sri Lanka, Mongolia, Italy, Portugal, Venezuela, Canada, Spain, Malaysia, Belgium, United Arab Emirates, Nepal, Bolivia, Yemen, Indonesia, United Kingdom, Costa Rica, China, Philippines, Egypt, Russia, Qatar, Lithuania, cyprus, Bahrain, Colombia, Lebanon, Slovakia, Gambia, Belarus, Netherlands, Denmark, Germany, Czech Republic.

Reviews

There are no reviews yet.