Showing all 6 results

-

Titanium Gr 22

Commercially pure titanium alloys contain small amounts of oxygen and iron that influence mechanical properties. Each commercial grade is produced to provide properties suited for different applications.

Grade 2 Unalloyed Ti (“Pure”) 50A alloy is the most commonly used and widely available grade of unalloyed titanium. It is non-magnetic. This alloy has been approved for sour service use under the NACE MR-01-75 Standard.

Grade 2 is widely used because it combines excellent formability and moderate strength with superior corrosion resistance. This combination of properties makes CP Grade 2 titanium a candidate for a large variety of chemical and marine as well as aerospace and medical applications.

Titanium Grade 2 UNS R50400, Of the four commercially pure (C.P.) titanium grades, Grade 2 is typically used in applications that require superior corrosion resistance in various aggressive media. Corrosion resistance is similar between these four C.P. grades but mechanical properties vary along with varying oxygen and iron contents.

Typical applications for the “C.P.” grades include chemical process, petroleum refining, biomedical as well as heat exchangers in an array of different applications. Continuous service temperatures can reach up to 800°F with occasional, intermittent service at 1000°F.

Titanium’s C.P. grades corrosion resistance comes from a strongly adherent, stable, protective oxide film, which forms in the presence of oxygen. This film makes the commercially pure titanium grades resistant to most oxidizing, neutral and inhibited reducing as well as mildly reducing environments. Strong reducing media may cause heavy corrosion.

-

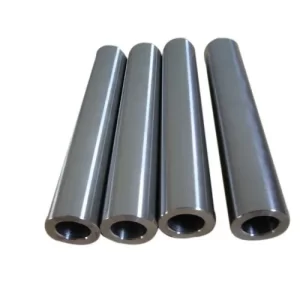

Titanium Gr 4

Commercially Pure Titanium Grade 4 is the highest strength pure unalloyed Titanium with high oxygen and extra high strength. Grade 4 displays the highest strength of all the unalloyed CP grades. It combines excellent corrosion resistance with good formability and weldability. Mainly used in hydraulic and instrumentation tubing. Generally chosen for its corrosion resistance in a variety of chemical process equipment as well as marine and airframe applications. It can be used for parts requiring strength up to 400 ° F and oxidation resistance to 600 ° F.

-

Titanium Gr 6

Titanium alloys are light weight and have excellent corrosion resistance, very high tensile strength and toughness. These properties remain unaffected to a great extent even at extreme temperatures. The durability of these alloys make them viable for several industries such as aerospace, military, automobile, consumer electronics, and sports equipment.

Grade 6 Ti-5Al-2.5Sn alloy has high service temperature of 480°C (896°F), medium strength, and excellent weldability and fabricability. This alloy has good oxidation resistance and microstructure stability; however it is not heat-treatable.

-

Titanium Gr 7

Titanium alloys have several advantageous attributes that allow their use in industries like automobile, consumer electronics, military, aerospace, medical, marine, and sports equipment.

Grade 7 Ti-0.15Pd alloy is highly resistant to corrosion in reducing acids and localized attack in hot halide media. The presence of palladium helps to enhance the alloy’s corrosion resistance. This alloy is similar to grade 2, and possesses medium strength and ductility.

-

Titanium Wire Gr 5

Grade 5 Titanium (Ti-6Al-4V) Wire UNS R56400

Grade 5 Titanium (Ti-6Al-4V) is stronger than commercially pure titanium alloys.

Titanium Gr.5 Spool Wire, Titanium UNS R56400 Welding Wire, Grade 5 Titanium Filler Wires, Ti. Alloy Gr.5 MIG wire, Grade 5 Titanium Tig Wire, Titanium Gr.5 Electrode Wire, Titanium Gr.5 Coil Wire, ASTM B863 Ti Gr.5 Flux Cored Wires, Titanium R56400 Wire, Ti. Alloy Gr.5 Wire Suppliers and Exporters.

Titanium UNS R56400 Tig Wire, Titanium UNS R56400 Spool Wire, Titanium UNS R56400 Bright Wire, Titanium Gr.5 Welding wire, Titanium 3.7165 Coil wire, Grade 5 Titanium Electrode Wire, Exporters of ASTM SB863 Titanium Gr 2 Wire, Titanium R56400 MIG Wire Manufacturer in India.