Description

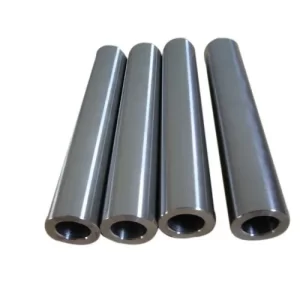

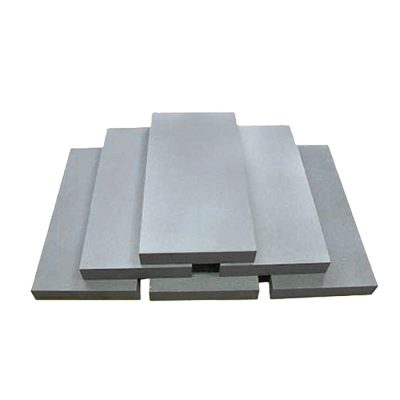

Grade 5 Titanium (6-4) Shaped, Flat, Square, Round, Fine Wire, Plated and Un-plated ASTM B265, AMS 4911, AMS 4928

GRADE 5 TITANIUM 6AL-4V ALLOY DESCRIPTION

Stronger than commercially pure titanium alloys is titanium 6Al-4V (Grade 5). Containing 6% Aluminum and 4% Vanadium, this alloy has many advantages, among them being that the alloy is heat treatable, has an excellent combination of strength, corrosion resistance, weldability and formability.

APPLICATIONS

- Tension set rings

- Bolts

- bicycle part

- Biomedical implant

- High-temperature structural applications in the aircraft industry

CHEMISTRY TYPICAL

Titanium: Balance

Vanadium: 4.0

Aluminum: 6.0

Hydrogen: 0.015 max

Nitrogen: 0.02 max

Carbon: 0.10 max

Iron: 0.25 max

Residual each: 0.10 max., total 0.40 max

COMMON TITANIUM GRADE NAMES

| Name | Code | Description 1 | Description 2 | ASTM | AMS | UNS |

| Grade 5 Titanium | 6-4 | Titanium Alloy 6% Aluminum, 4% Vanadium | R56400 |

PHYSICAL PROPERTIES

Density, 0.16 lbs/in³, 4.43 g/cm³

Mean Coefficient of Thermal Expansion: in/in/°F (mm/m/°C):

70- 212°F (20- 100°C): 4.78 x 10 (8.6)

Thermal Conductivity: BTU-in/h-ft-°F (W/m-°K):

At 70°F (21°C): 46.5 (6.7)

Modulus of Elasticity: KSI (MPa)

16.5 x 10³ (113.8 x 10³) in tension

Melting Point: 3020°F (1660°C)

MECHANICAL PROPERTIES AT ROOM TEMPERATURE

PROPERTIES: ANNEALED (TYPICAL)

Ultimate Tensile Strength: 135 KSI (950 MPa)

Yield Strength (0.2% offset): 125 KSI (880 MPa)

Elongation: 15%

Hardness: Rc 34

PROPERTIES: TEMPERED

Contact Ulbrich Wire with requirements.

ADDITIONAL PROPERTIES

TI-6AL-4V CORROSION RESISTANCE

Refer to NACE (National Association of Corrosion Engineers) for recommendations.

FINISHES

Inquire with Ulbrich Wire

FORMS

- Continuous Coils

- Cut to length

- Precision cutting

HEAT TREATMENT OF TI-6AL-4V

Titanium 6-4 (Grade 5) be hardened by cold working and heat treating.

Reviews

There are no reviews yet.