Description

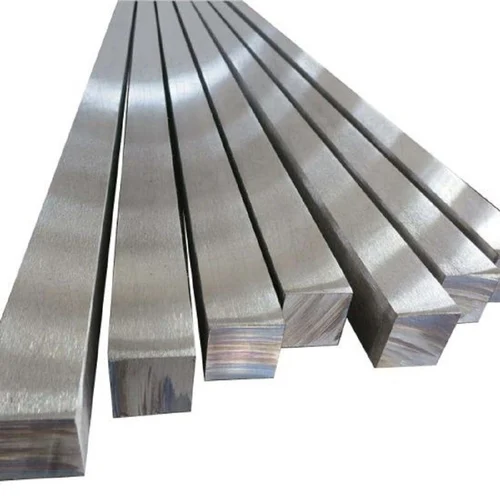

ASTM B425 Incoloy 825 Forged Square Bars, Incoloy 2.4858 Forged Square Bars, Incoloy 825 Forged Sqaure Bars, Incoloy 825 Forged Sqaure Bars Exporter, Incoloy N08825 Forged Square Bars, Incoloy 825 Forged Rods Stockist In Mumbai India.

825 Forged bars are Ferritic in nature and they contain niobium which helps the Forged Bars to provide deep drawing properties and Good brightness. Titanium in the 825 Forged Bars helps them to resist the stress corrosion cracking. The 825 Forged Bars also have great stability properties. We at VIP Ferromet provide certain documents with our 825 Forged Bars that ensure the quality of these Forged Bars. Some of the documents that we provide include Certificate of origin legalized/attested by Chamber of Commerce or Embassy, Material Traceability Records, Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Raw Materials Certificate, Third Party Inspection Report, 100% Radiography Test Report, etc.

Applications of the 825 Forged Bars are primarily found in the catering industries. Automotive-exhaust system components are made using the 825 Forged Bars. Food and kitchen equipment, Heat exchangers and architectural structures are also produced with the 825 Forged Bars.

Incoloy 825 Forged Square Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | ЭП703 | NFE30C20DUM | NCF 825 | NA 16 | NiCr21Mo | XH38BT |

Chemical Composition Of Incoloy 825 Forged Square Bars

| Grade | Ni | Cr | Fe | Mb | Ti | Cu | Mn | C | S | Al | Si |

| Incoloy 825 | 38.0 – 46.0 | 19.5 – 23.5 | 22.0 min | 2.5 – 3.5 | 0.6 – 1.2 | 1.5 – 3.0 | 1.0 max | 0.05 max | 0.03 max | 0.2 max | 0.5 max |

Incoloy 825 Forged Square Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Reviews

There are no reviews yet.