Description

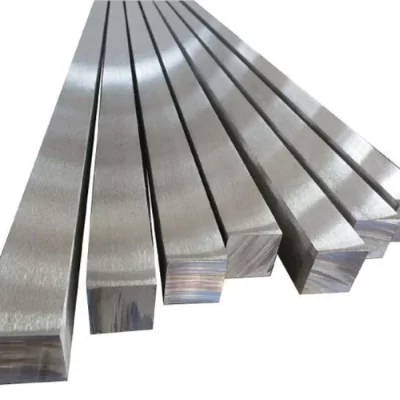

Our teams of talented professionals are dedicated towards managing the production and export of Incoloy 825 Square Bar Products in a wide range. With abundant technical manpower support, we manufacturer these Incoloy 825 Square Bar with utmost care on the quality of the product. We are an ISO 9001:2008 registered company, and have been recognized as one of the world’s leading stockists and manufacturer of quality metals for over two decades and are committed to quick responses, unsurpassed quality, competitive pricing, reliable deliveries and an exhaustive inventory.

We manufacture Incoloy 825 Square Bar in India for export all around the world.. Super metal manufacturing co. is a leading manufacturer of Incoloy 825 Square Bar and many other products. Our streamline manufacturing process is in compliance with the international quality standards that help us to retain our position as one of the top notched Incoloy 825 Square Bar exporters. With over years of experience in manufacturer, suppliers and stockists our products.As a result to that our export account today is in various countries like Saudi Arabia, UAE, Vietnam, South Africa.

Most metal produced by a steel mill or aluminium plant is formed (via rolling or extrusion) into long continuous strips of various size and shape. These strips are cut at regular intervals and allowed to cool, each segment becoming a piece of bar stock. A good analogy is pasta-making, in which lumps of dough are extruded into various cross-sectional shapes; cut into lengths; and then dried in that form. The cross-sectional shapes of pasta vary from simple bar or tube shapes (such as linguine or penne) to more elaborate extrusions (such as rotelle, fiori, or rotini). The same is true of metal bar stock. The most common shapes are round bar (also called rod), rectangular bar (including square bar, the special case of equal sides), and Squareagonal bar (usually called Square bar for short). Tube and pipe are similar, but have hollow centers and are traditionally not called “bar” in industrial usage. (However, a product called hollow bar, essentially tube but with custom-orderable OD and ID and thus custom wall thickness, is marketed for lathe bar work which can benefit from obviation of drilling and rough boring.) Also similar in concept, but not called “bar”, are the common structural shapes such as angle stock and channel stock. These are commonly available in steel and aluminum; the names “angle iron” and “channel iron” are still commonly used (informally) even though their literal namesake, wrought iron, has been replaced by steel and aluminum for most uses.

Incoloy 825 Square Bar Specification

| Standards | Designation |

|---|---|

| ASTM | B160 |

| Length | Diameter |

|---|---|

| 2-6m | 6mm-800mm |

Incoloy 825 Square Bar Chemical Composition

|

ELEMENT

|

Incoloy 825 Square Bar

|

|---|---|

|

NI

|

99.0 min

|

|

CU

|

0.25 max

|

|

FE

|

0.40 max

|

|

MN

|

0.35 max

|

|

C

|

0.15 max

|

|

SI

|

0.35 max

|

|

S

|

0.01 max

|

Incoloy 825 Square Bar Physical Properties

| DENSITY (G/CM 3) |

8.89

|

| DENSITY (LB/IN 3) |

0.321

|

| MELTING POINT (°C) |

1435 – 1446

|

| MELTING POINT (°F) |

2615 – 2635

|

Incoloy 825 Square Bar Mechanical Properties

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|---|

|

Square & Bar

|

Hot Finished

|

60-85

|

15-45

|

55-35

|

45-80

|

|

Square & Bar

|

Cold Drawn/Annealed or Hot-Finished/Annealed

|

55-75

|

15-30

|

55-40

|

45-70

|

Tensile Strength : Unit – ksi (MPa) , Minimum

Yeild Strength : 0.2 % Offset , Unit – ksi (MPa) , Minimum

Elongation : in 2″, Unit : % , MinimumValues as per ASTM B 160

Reviews

There are no reviews yet.